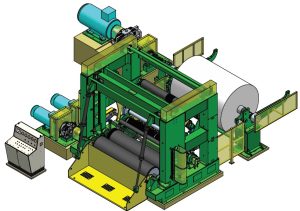

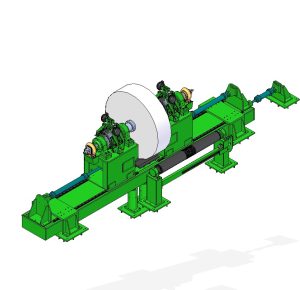

REWINDER

- Winder designed for maximum operating speed of 2000mpm.

- Winder maximum Deckle of 7000MM.

- Twin Drum Winder (Online shear cut / Wrap around shear cut / Online with individual Slitter motors).

- TNT (Auto Torque / Nip / Tension) control system.

- Unwind with Brake Generator / Water cooled brake drum.

CORE CUTTING MACHINE

Suitable for 3″ core cutting.

M.S. fabricated base frame with guide rods/rollers arrangement for core feeding. 2 Nos. M.S rollers with housing assembly mounted on the frame. The both rollers driven by suitable geared motor through belt arrangement. The core cutting knife assembled on the holder, which is mounted on the base plate with runner blocks. The entire knife assembly sliding on the linear guide way for up / down movement through pneumatic cylinder. The core cutting actuation by pneumatic cylinder. The above machine having common centre shaft with adoptable mandrel for 3″ cores with support rollers for the core pipes which is suitable for max. cutlength is 6 meter New core pipe.

FINISHED REEL STOPPER

Finshed Reel Stopper Kept after rewinder section to stop the reel movement and hold it for marking purpose.

KNIFE HOLDERS

Knife Holders suitable for various application of slitting like Manual Knife Holder, Swivel Engage Pneumatic knife holder and Double acting Pneumatic Knife Holders

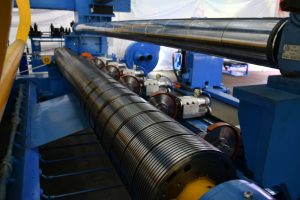

SLITTING STATION

Various type of Slitting Stations we supplied with our Rewinder for High Speed Slitting application.

Smooth and Even surface cutting edge.

TRIM BLOWER

Collecting Trim from the slitting station and deliver the chopped trim paper to Broke Pulper or UTM pulper.

Suction Length of 20 Mtrs and Delivery Length of 70 Mtrs

Trim Width from 25 mm to 75 mm

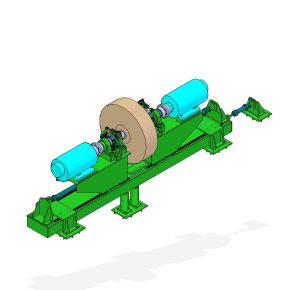

UNWIND SECTION

Unwind Stand with Spool Clamping and Ejecting Empty Spool with Holding Lever.

Hydraulic Operation to Hold reel while operating rewinder in High Speed and Ejecting Empty spool upto end of the Holding Arm.

Pneumatic Operated Gear Coupling Engagement with Reel Spool.

Motorized Movement for Length Deckle Adjustment with friction free LM Guide and Block Bearings.

DUST COLELCTION SYSTEM

We Provide best solution to supply dust free paper to your customer.

Dust in the Tissue Paper and White Duplex Board paper impact the customer satisfaction.

We are supplying optimized solution with required components and will take responsibility from Design to Commissioning

SALVAGE REWINDER

Customized Unwind Stand for converting the rejected reels from rewinder.

Upto Deckle of 2200 MM and Speed of 800 MPM

With Web Aligning System and Hydraulic Loading Arms

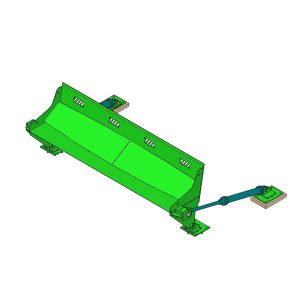

LOWERING CRADLE

Separate Lowering Cradle which can be adopted for any kind rewinder to unload the Finished Reels from the rewinder to floor properly.

It will act as a safety door while rewinder is running at high speed.

It is operated through Hydraulic Cylinder and Control with Sensors